Parameters Table

Processing parameters

| model |

| 9B-5L/P | 9.6B-10L/P |

|

| Fixing size | Grind(mm) | Φ638xΦ234xt30 | Φ615.5xΦ383.5xt35 |

|

| polishing(mm) | Φ640xΦ232xt30 | Φ621.5xΦ379.5xt35 |

|

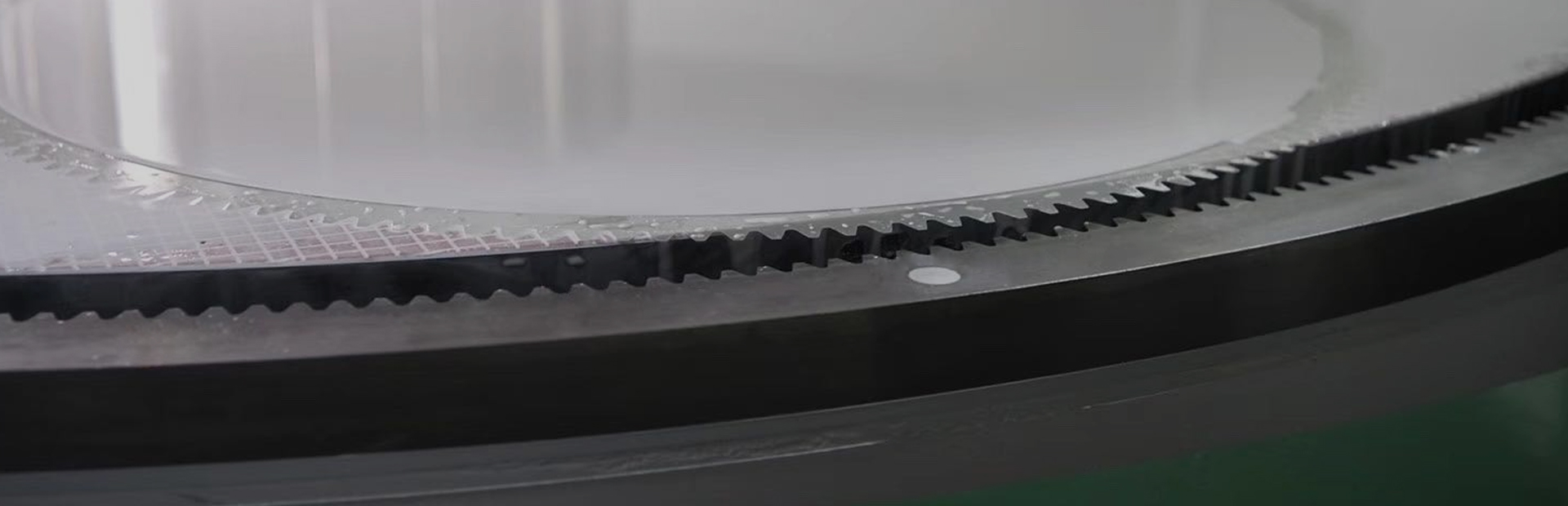

| Cruising star wheel parameters | Modulus | DP12 | DP12 |

|

| Number of teeth | Z108 | Z66 |

|

| Pitch circle(mm) | 228.6 | 139.7 |

|

Drive way

| 3motor | . | . |

|

| 4motor | . | . |

|

Number of cruise ships

| 5 | 10 |

|

Maximum machining diameter(mm)

| 150 | 90 |

|

Maximum processing thickness(mm)

| 66 | 66 |

|

Other parameters

| Central tooth, ring gear | Can use electrical buttons to automatically ascend | power | Input: 3-phase 380V 50HZ Current capacity: 30A Main circuit: 3-phase 380V50H Control circuit: 110V |

| Processing pressure | Minimum working pressure: 5KG (50N) Standard maximum working pressure: 150KG (1500N how to expand according to the use requirements Pressure control method: precision weighing sensor + PLC + electronically controlled proportional valve to achieve closed-loop feedback control of pressure, real-time monitoring and real-time calibration of pressure, to ensure the accuracy and stability of pressure. | Rotating speed | Lower fixing: 1 ~ 45RPM Upper fixing: 1 ~ 15RPM Center gear: 1 ~ 20RPM Ring gear: 1 ~ 16RPM |

| Water source | 15MPa 20L /Min | Use environment | ●15~35. C ●Humidity: Below 85%, sewage is condensed; ● Air quality: non-corrosive, non-flammable, harmful gas, non-polluting dust, etc. |

| Gas source | 0.5~0.6MPa 75L /Min | Drain bellows | Inner diameter Φ60 |

Features

Using 4-Motor (3Motor motion mode optional motion mode, namely the upper fixed plate, lower fixed plate, ring gear, center gear motors can be independently controlled, without changing the ring gear, The situation of the direction of rotation of the central tooth

Under the circumstances, it is easy to realize the forward and reverse rotation of the star wheel, and the forward and reverse rotation of the star wheel can be used to process the workpiece stably so as to realize the self-adaptive fixation of the fixed disc. The central tooth can also be used to reverse the fixation independently.

4-Motor movement mode makes the power source more dispersed, the machine is more stable, the noise is lower, and the precision is higher; the adaptability of the star wheel operation is improved, and the star wheel wears It can also be reduced to a minimum,

Greatly extend the service life of the cruiser.

The CPU can assign the rotation speed of the upper and lower fixing plate, the lower fixing plate, the center gear, and the ring gear by itself, or the operator can separately set the upper and lower fixing plate and the center gear according to their own calculations and experience. , The ring gear is set appropriately

Rotation speed can facilitate the operator to better design the rotation and revolution trajectory of the workpiece, and set any rotation and revolution ratio to achieve the best processing conditions and optimal processing results.

The ring gear and the center tooth move up and down at the same time, making it easier to pick and place the workpiece;

SMC precision electric proportional control valve + pressure sensor realizes stable pressure changes, which can eliminate excess load and extra impact to the greatest possible extent, and protect the safety of the processed workpiece;

The pressure of the plate and the starting plate can be manually set manually to maximize the safety of the processed workpiece.

Mitsubishi large-size digital human-machine interface + Mitsubishi high-quality PLC module, which can store 20 20-step procedures inside, greatly reducing the technical requirements for operators and greatly improving product qualification Rate.